How to choose proper production process for heat resistant steel castings

There are mainly 3 processes to produce heat resistant steel castings in China now, they are:Shell-mould Casting

Water glass composite shell investment casting

Silica sol shell investment casting

So which one is better? Today, let’s discuss it, hope it’s helpful for you to choose the proper casting process

Difference 1, Concept difference:

Shell-mould Casting is a casting process by pouring resin covered sand into heated pattern to form the mold.

Water glass composite shell investment casting use low temperature wax to make wax pattern, use water glass quartz sand as the first and second coatings, use silica sol zircon sand as the third coating to form the mold.

Silica sol shell investment casting use middle temperature wax to make wax pattern, use silica sol zircon sand as three coatings to form the mold.

Difference 2, Surface finish and defects

Shell-mould Casting surface is better than green sand, with less inside defects

Water glass composite shell investment casting surface is better than shell casting, and inside defects is less.

Silica sol shell investment casting surface is the best among the 3 processes, inside defects is less too.

Difference 3, products shape, size and weight:

Shell-mould Casting is suitable for parts with simple shape, size less than 800mm, weight less than 30kgs.

Water glass composite shell investment casting is suitable for parts with complex shape and weight less than 50kgs

Silica sol shell investment casting is suitable for parts with complex shape and weight less than 40kgs

Difference 4, Casting tolerance

Shell-mould Casting can meet tolerance CT7-CT8

Water glass composite shell investment casting can meet tolerance CT5-CT6

Silica sol shell investment casting can meet tolerance CT4-CT5

Difference 5, Price (use heat resistant steel material 1.4852 as example)

Shell-mould Casting production cycle is short and efficiency is high, its price is the cheapest, about US $10/kg

Water glass composite shell investment casting price is a little higher, about US $13/kg

Silica sol shell investment casting price is the highest, it’s about US $15/kg

So, Shell-mould Casting is suitable for grate bars used in incinerator, and heat treatment fixtures such as trays, baskets and grids are suitable for both Water glass composite shell and Silica sol shell investment castings.

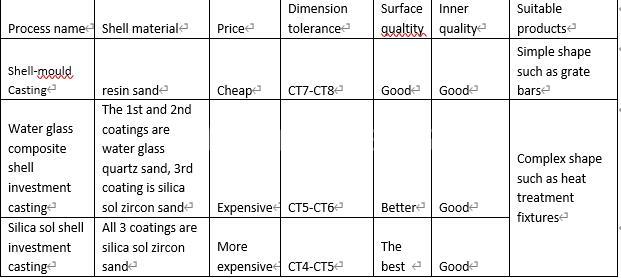

Following is a chart to give you brief idea about the above comparison:

Conclusion:

1, There is no obvious difference on inner quality among the 3 processes.

2, Shell-mould Casting is suitable for parts with simple shape and lower requirement on tolerance and surface quality.

3, If you pursue the economic value for complex shape parts, water glass composite shell investment casting is a good choice.

If you want to discuss more , leave your comment or send email: evakong@shinningcorp.com, I’m happy to share.