How to solve surface defect on heat resistant steel casting

How to solve surface defect on heat resistant steel casting

8 years ago, Shinning Metals received an investment castings order from our Germany client, it’s heat resistant steel castings, the material is 1.4740, weight is 0.76kgs, as it’s a small part, we decided to use colloidal silica shell process.

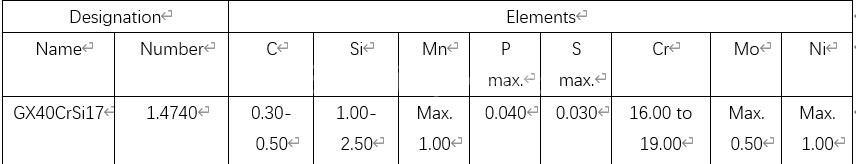

The chemical component is as below.

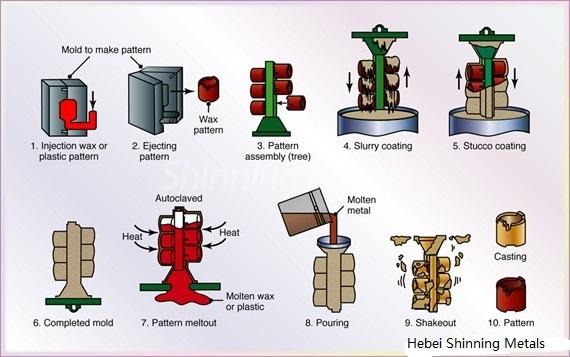

We started producing samples as per the below typical investment castings process:

After cleaning and shot blasting, we found there were many small black holes on the castings surface. We immdiately arranged meeting with our technical, production and quality department to analyse the root cause, after discussion together, all of us aggreed the black holes on castings surface may be caused by the below reasons:

1, Face coating and filter coating contained too much impurities.

2, Molten steel was over oxidated during melting process.

3, Shells were not baked suffient, there were residual chemical substances on the baked shell

After meeting, we started to check each possible cause one by one.

First we inspected the face layer and filter layer material in stock , the result was: all the layer components conformed to our national standard, so it’s not the layer material’s problem.

Then we checked the melting record, the molten steel was not over oxidated and deoxidization was good.

In the end, we inspected the remained shell, many off-white spots were found inside it, so we can just use this sign to confirm the root cause, the shell was not backed sufficent, the residual chemical substances on the shell reacted with molten steel.

To adress the problem,

1, We reduced the number of wax patterns on one tree from 6pcs to 4pcs, in order to increase the space among the wax patterns

2, Increse the shell baking time by 10 minutes

We applied these new methods to next sample production, and finally the castings surface was improved, it’s very smooth as below:

Thanks to the high efficiency team work, we subimmted samples to our customers in one month, and got sample approval finally.

Leave a comment or e-mail me :evakong@shinningcorp for any investment castings problem, I’m happy to talk and share.