Investment Casting Production Process

Do you know how investment castings are produced? Today let’s discuss it.

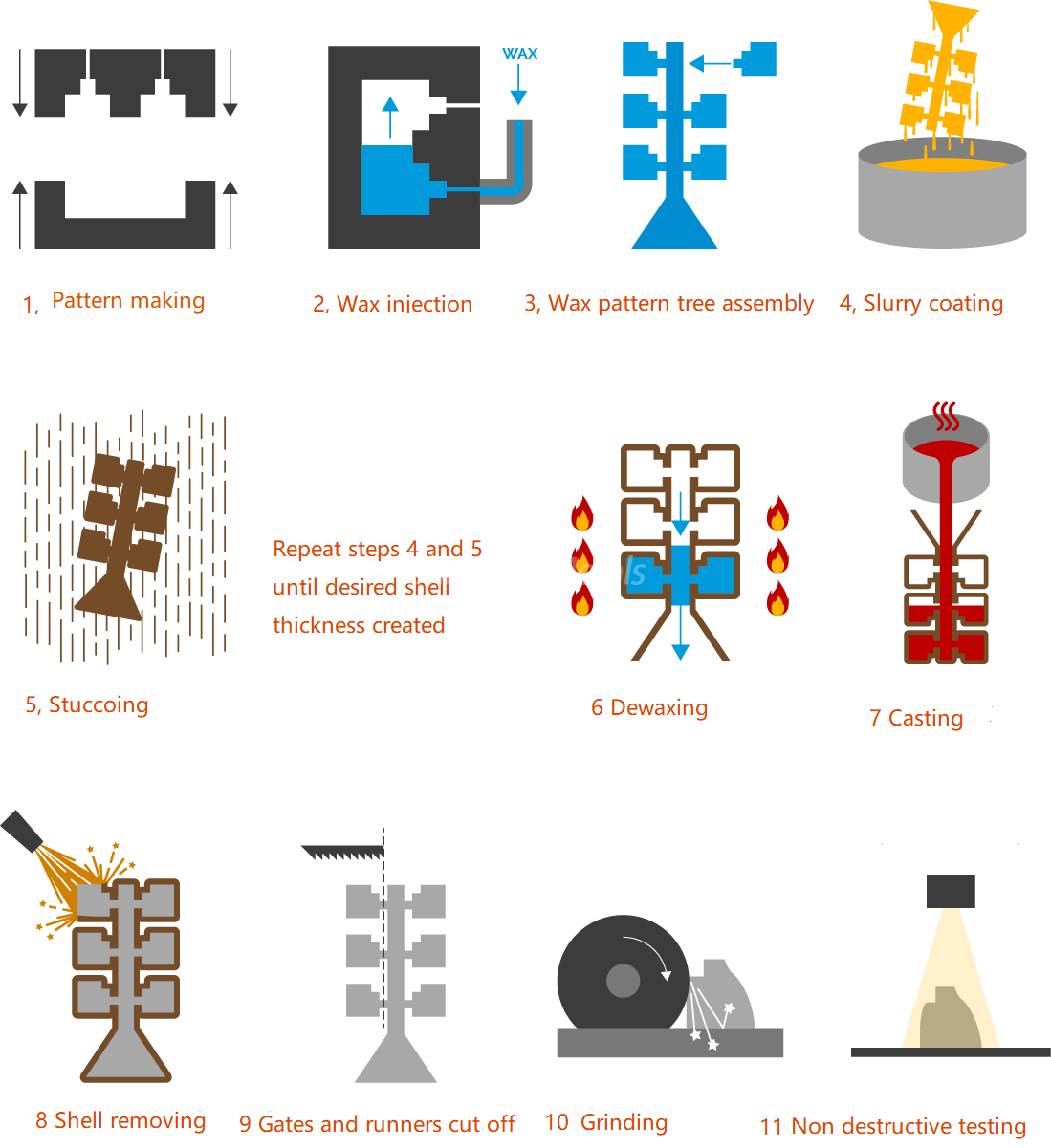

Following is a picture to give you a rough idea about investment casting process:

1. Pattern making: Make aluminum pattern which replicates the finished part.

In this process, the allowance for thermal contraction (i.e. shrinking) will be considered.

2. Wax injection: Inject heated wax into pattern

3. Wax pattern tree Assembly: The wax patterns are assembled onto runners and then a wax pattern tree is ready for dip into slurry.

In this process, the wax pattern quantity, gap and angle among patterns on one tree and pouring system will be considered.

4. Slurry Coating: The assembly pattern tree is dipped into slurry made of water glass quartz sand or silica sol zircon sand

5. Stuccoing: After the slurry coating is done, the wax pattern tree is covered with sand stucco, and sand stucco become dry in natural

Repeat Steps 4 and 5: Repeat steps 4 and 5 until a shell of the desired thickness is created. That thickness is determined by product size and shape, small and simple shape parts shell is thinner than big and complex shape parts. Once the ceramic shell has dried, it becomes sufficiently strong to retain the molten metal during casting.

6. Dewaxing: The entire assembly is placed in a steam autoclave to melt away most of the wax.

Then the entire assembly is baked in a furnace, during this process, any remaining wax soaked into the shell is burned out. And the residual wax pattern and gating material have been completely removed and the mold remains with a cavity in the shape of the desired cast part.

This high-temperature operation also increases the strength and stability of the shell. In addition, it helps to minimize the reaction of the shell and metal during pouring.

7. Casting: The molten metal is poured into the pre-heated mold cavity.

The temperature of molten metal is different for different material, the more alloy content, the higher of the molten metal.

8. Shell Removing: The shell is then removed through vibration by air-operated,

9. Cut Off: The gates and runners are cut from the casting.

10. Finishing: Various finishing techniques are then applied including grinding, sand blasting and coating to achieve the final surface needed. And machining will be applied if needed

11. Testing: Once the finishing operations are done, the parts are inspected for outer surface and inner surface quality. Visual, magnetic particle (for carbon steel) and fluorescent penetrant (for stainless steel and alloy steel) inspection is applied for outer surface, X-ray is applied for inner surface detection

To learn more about this process or to determine if it is a fit for your application, please contact evakong@shinningcorp.com